Digital forecaster for business| 01.10.2020

Every day we use the services of many companies go to the shops, cinemas, museums, ride the subway, fly in planes. Most of the companies with which we interact every day is

big business. In fact, as a result of his company’s activities (private and public) create the world that surrounds us and create consumers comfortable and safe conditions: the service

delivery also strive to quickly deliver goods, stores worried about compliance with social distance, the metro and Railways are trying to get rid of the “crush”.

The main difficulty that companies face in implementing such projects is a service processes a large number of people and the uncertainty caused by the superposition of many

factors on each other.

Simulation is one technology, which is used in such situations. In fact, this new modelling approach for fast creation of complex models of complex business and

public system. Unlike conventional modeling techniques (e.g., Excel), in which we formulas linking cells between them, the simulation model uses agent-based methods

modeling (in the model the numbers and the agents/objects that can move in space, interact among themselves, exchange messages), discrete-event simulation (in

the model, as in life, there is a time in which the events occur, related to each other) and system dynamics (a method of describing the dynamics of complex business systems through streams and reservoirs).

Simulation allows you to play real-life scenarios, when your computer like a live process. You can simulate very complex systems that are difficult to put in the function

or predict, as the number of participants can be very large. Through this increased efficiency of social security systems as public enterprises and for

business in the commercial sector.

Where helpful technology to improve the lives of people

There are already many cases in Russia and abroad in which companies could improve the lives of people with the help of simulation.

For example, was carried out a project on simulation of the Polytechnic Museum (Moscow, New Square). There was a task to simulate perehoditi in the Museum, to understand where and in what quantity

post services: ticket office, ticket terminals, closets and even toilets, so to avoid the “crush” and queues, increase the level of comfort of the visitors of the Museum.

Another topical subject is the return to the office after the pandemic. Many companies are interested in building a model of office work in order to understand how to minimize the risk of infection

employees: how to organize the routes of the people, to minimize contacts.

Metro, Railways, airports create a simulation model to improve throughput, which helps to organize the services so that people do not have long to stand out in the crowd

and queues.

The company owns a large private railway infrastructure in remote towns, order dispatching model, which helps to plan the operation of locomotives in a timely manner to deliver to CHP –

coal, stores, products, and plants – raw materials.

The defence sector is very interested in modeling of air attacks, such models allow to generate the optimal strategy for protection of population in case of attack.

The aircraft manufacturers such as Airbus, create a simulation model of the cabin, which help to understand how best to place the oven to heat up meals, seats so that

to serve passengers faster and not block the aisles.

Where the useful technology to increase business performance

The actual task of major FMCG-companies – reduction of logistics costs. Simulation and optimization models allow to find the configuration of the circuit in which the level of customer service

sohranitsya at the same level, while total logistics costs – lower. For example, this project is now being implemented for a leading foreign manufacturer of beverages. In addition to the effect on cost reduction

in these projects, there are indirect effects: the model allows to analyze different “risky” scenarios and choose the best package of measures that will reduce possible negative consequences

the implementation risk.

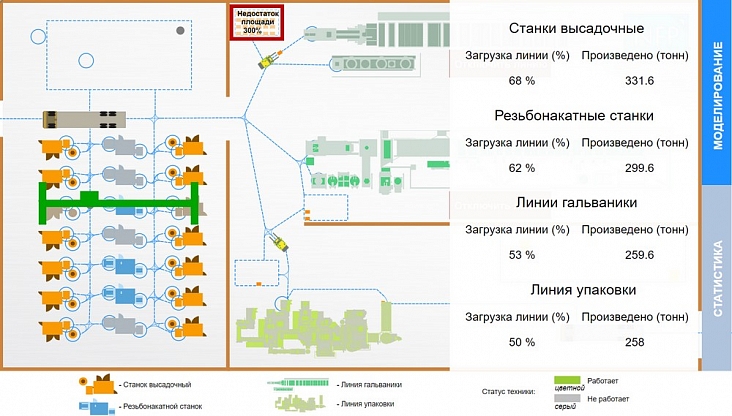

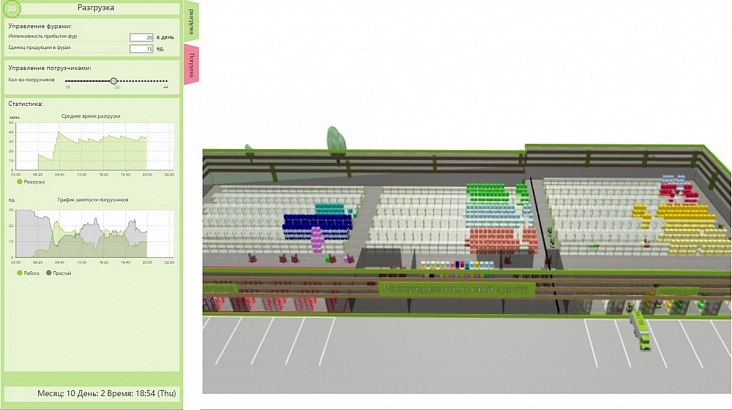

Fairly complicated project was to develop a model plant for the production of fasteners. The company-the customer’s task was to increase production capacity. Needed

to make the analysis of investment risks (to assess whether it achieved the required KPI to increase the volume of production) and optimize new manufacturing processes (to avoid filling the buffer

areas to properly distribute the load on production centres).

On the basis of the data collected was developed accurate digital model shop with an interactive interface to configure scripts. After you have conducted 100 experiments with different values of parameters

gaps have been identified in the workplace. For example, in the process model storage area before the electroplating line is filled with 100%. A year later the lack of space was more than 40%.

The uneven distribution of machines in the shop and containers from blanks required a large number of trucks. The only one in the shop girder crane did not allow for the necessary amount

production due to breakdowns and repairs. To fix these problems has changed the content of the workshop in the model were chosen such configuration, where the placement of the equipment would not hurt

to produce the required output. Also made recommendations on the extra beam of the crane and increase the number of trucks for the growth of the entire workshop

at least 7%.

In a large metallurgical company has been created a simulation model of the coal handling in the framework of the railway infrastructure of the customer (the transportation of coal from mines and quarries to the enrichment and

transportation of coal to thermal power station). The task was difficult because the railway infrastructure had to take into account many parameters. Was eventually used elements of W/d paths for markup

space, standard agents like Train and Car that allowed him to capture in the model the features of the device paths (arrows and interchanges), the movement of trains, the operation of the clutch and

uncoupling of wagons.

Two cornerstones in simulation modeling is obtaining accurate input parameters (depends on the accuracy of the model) and choose the right level of abstraction (detail

model) corresponding to the problem being solved.

Input data, such as modeling the flow of visitors metro to the “Internet of things” (video, various sensors, tags), or the old fashioned way, with

assistance on-site inspections.

Basing THEM digital double allows businesses to predict and to create a competitive advantage. Applying the technology of simulation, we can calculate

the behavior of the object or subject at different stages of life, to avoid danger and minimize risks.

Sergey LOZHKIN,

managing partner at NFP

Andrew GARIFUNA,

head of “simulation”, NFP

Computer simulation

Journal: Journal IT-News, Subscription to magazines